Industrial Software — Engineered for Your Production

At ASA-Projekt we design and develop intelligent software that powers modern production. From advanced control systems to full digital integration — we turn complexity into clarity.

Our approach is based on experience, precision, and a deep understanding of industrial processes. We develop custom applications that enhance control, visibility, and management across your entire operation — fully aligned with Industry 4.0 standards.

No two production sites are the same — and neither are our solutions. We build dedicated industrial applications that automate, monitor, and optimize your workflows, based on a thorough analysis of your processes and objectives.

PLC Programming (Control level)

We develop robust PLC (Programmable Logic Controller) programs tailored to your specific machinery and processes. Whether it’s a standalone system or part of a larger automation setup, our PLC programming ensures precise, consistent control and seamless communication with higher-level systems like SCADA, DCS, and MES. Our expertise spans across Siemens, Allen-Bradley, Beckhoff, and other major platforms — giving you flexible and future-ready control at the core of your operations.

HMI Interfaces (Process visualization)

We design intuitive HMI panels that offer operators clear, safe, and immediate access to key machine functions. Our custom-built interfaces reduce complexity and ensure reliable interaction between people and machines.

SCADA Systems (Real-Time Control & Monitoring)

We implement SCADA solutions that keep your production under control — minute by minute, second by second. Get instant access to key parameters, alarms, and performance metrics from anywhere, improving operational efficiency and reducing downtime.

DCS Systems (Supervisory level)

For complex, continuous processes, we implement Distributed Control Systems (DCS) that ensure reliable and coordinated control across every layer of your plant. With scalable architecture and centralized data handling, our DCS solutions offer high stability, real-time performance, and seamless integration with your existing infrastructure. Whether it’s DCS System for chemical processing, energy, or construction industry — we tailor the system to your unique operational environment.

We offer a complete range of engineering services to support your project from concept to commissioning and beyond. These include process analysis and system design, platform selection, development of control logic, HMI/SCADA configuration, and system simulation (FAT). We also handle hardware supply and installation, on-site commissioning (SAT), and integration with higher-level systems such as MES and ERP. To ensure long-term performance, we provide operator training, technical documentation, remote monitoring, ongoing maintenance, and system upgrades — everything you need for a reliable and future-ready control infrastructure.

MES Integration (Production Management)

To stay competitive, production must be smart, agile, and connected, we help you implement powerful MES systems that provide full visibility over production, quality, and resource management — all integrated with your automation layer and ERP system.

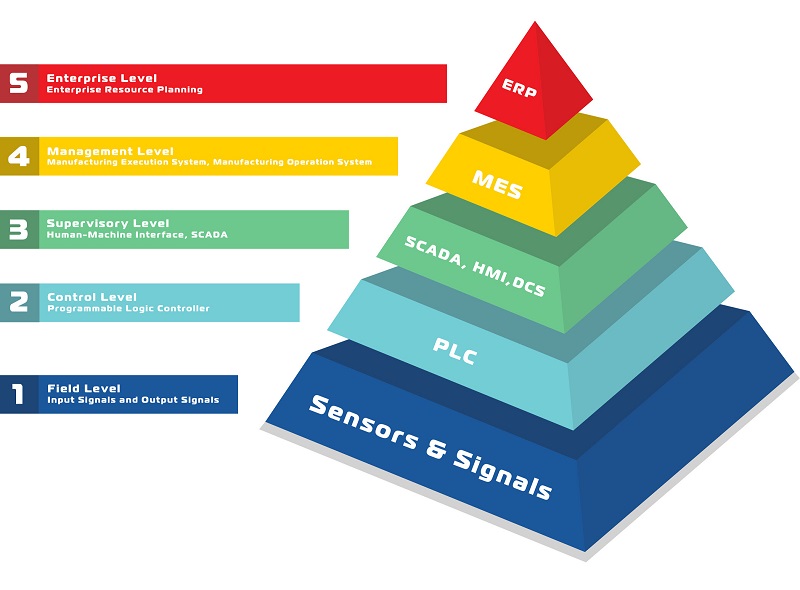

We cover all stages of automation — from field-level signal acquisition to integration with enterprise systems. This enables us to implement high-level, structured integration, delivering solutions across all layers of the industrial automation pyramid.