Home HMI

HMI Panels Play a Key Role in Industrial Process Automation

Operator touch panels play a crucial role in automating industrial processes, providing a convenient and functional interface between humans and equipment. Programming them requires consideration of multiple factors to unlock their full functional potential.

Visualization

Panels provide a clear representation of technological processes in text and graphic formats. Graphs, diagrams, indicators, and panels displaying current parameter values help the operator quickly assess the system’s status.

Emergency Messages

Implementation of functions for managing, recording, and processing emergencies. In the event of a system failure, the panel should issue notifications, indicate the cause of the problem, and log the event in the archive.

Real-Time Control

Allows the operator to enter parameters, start and stop processes, select operating modes, or choose recipes. This is one of the most critical functions affecting ease of control.

Data Exchange

Touch panels integrate with various industrial systems, including PLC, SCADA & MES.

Data exchange is critical for synchronization and management.

Access Rights Administration

Includes user role management, activity logging, and tracking of events related to process interventions.

Working with Performance Indicators

Data archiving, report generation, trend and graph analysis, as well as organizing the printing of important information.

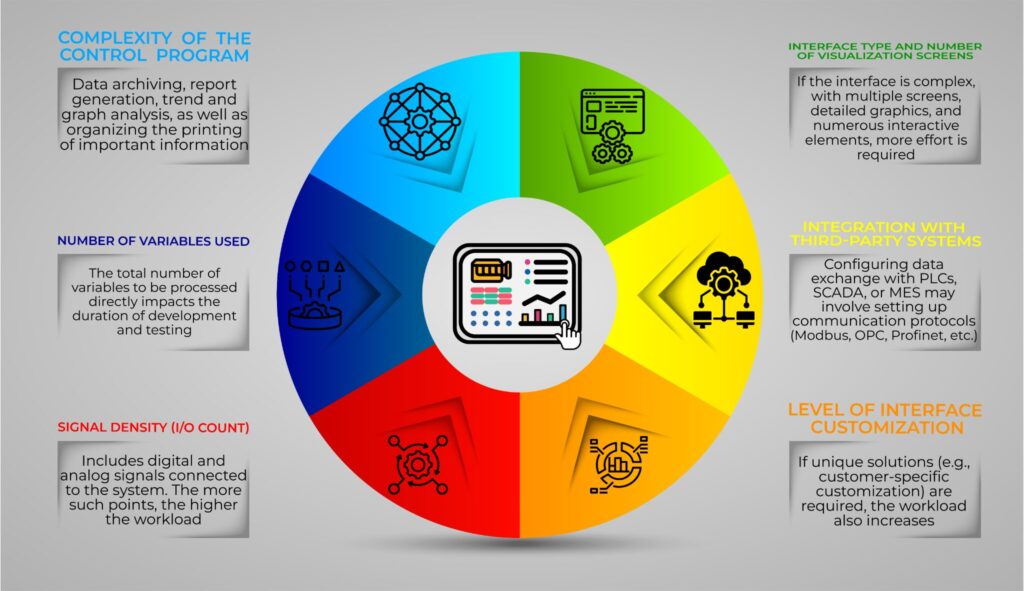

Factors Affecting the Cost of HMI Programming

ASA Projekt – Professional HMI and PLC Programming for Industrial Process Automation

Our team provides a full range of services for the development and implementation of HMI and PLC systems. We ensure:

You receive a ready-made solution that meets your production requirements, considering its specifics and scale. We offer a personalized approach, minimal development time, and support at all stages of implementation.

ASA-Projekt – Automation That Works for You!